Applications

Primers

OVERVIEW

Primers, or undercoats, are most commonly used for their ability to seal the surface and provide greater adhesion and durability for the resultant topcoats.

SOLUTIONS

Chemco have developed a market leading selection of Primers for a wide range of applications. These exhibit distinct and valuable properties:

SOLUTION

Solvent-Free Primer Finish

RS 500P is a solvent-free, wet & rust tolerant primer or primer-finish epoxy coating system.

The use of special sacrificial fillers enables the system to be applied to surface standards as low as WJ-4, St 2.

The system’s long-term performance is based on completely sealing (porous-free film) and arresting the rust totally.

SOLUTION

VOC Compliant Primer Finish

RL 500PF is a wet & rust tolerant, two pack, high solids epoxy coating.

It can be utilised either as a one coat primer/finish with good UV resistance or as a high performance coating which can be over-coated with colour topcoats.

SOLUTIONS

Concrete Primers

RH 800 is a solvent-free, wet tolerant floor coating.

It is typically utilised as a primer which allows green concrete to be primed as soon as new concrete has set. It can be applied onto fresh concrete whilst it is still green.

RB 800P is a solvent-free floor coating.

It is typically used as a primer for sealing concrete substrate prior to the application of a protective coating system.

SOLUTIONS

Water-based Epoxy Primers

RX 500P is a solvent-free, water-based epoxy coating.

It can be utilised as a multi-purpose primer for application to the most difficult substrates.

RP 800 is a solvent-free, water-based floor coating.

It is suitable for application in environments where solvents would be hazardous or have a detrimental affect upon the operating process or products.

SOLUTIONS

Vinylester Primers

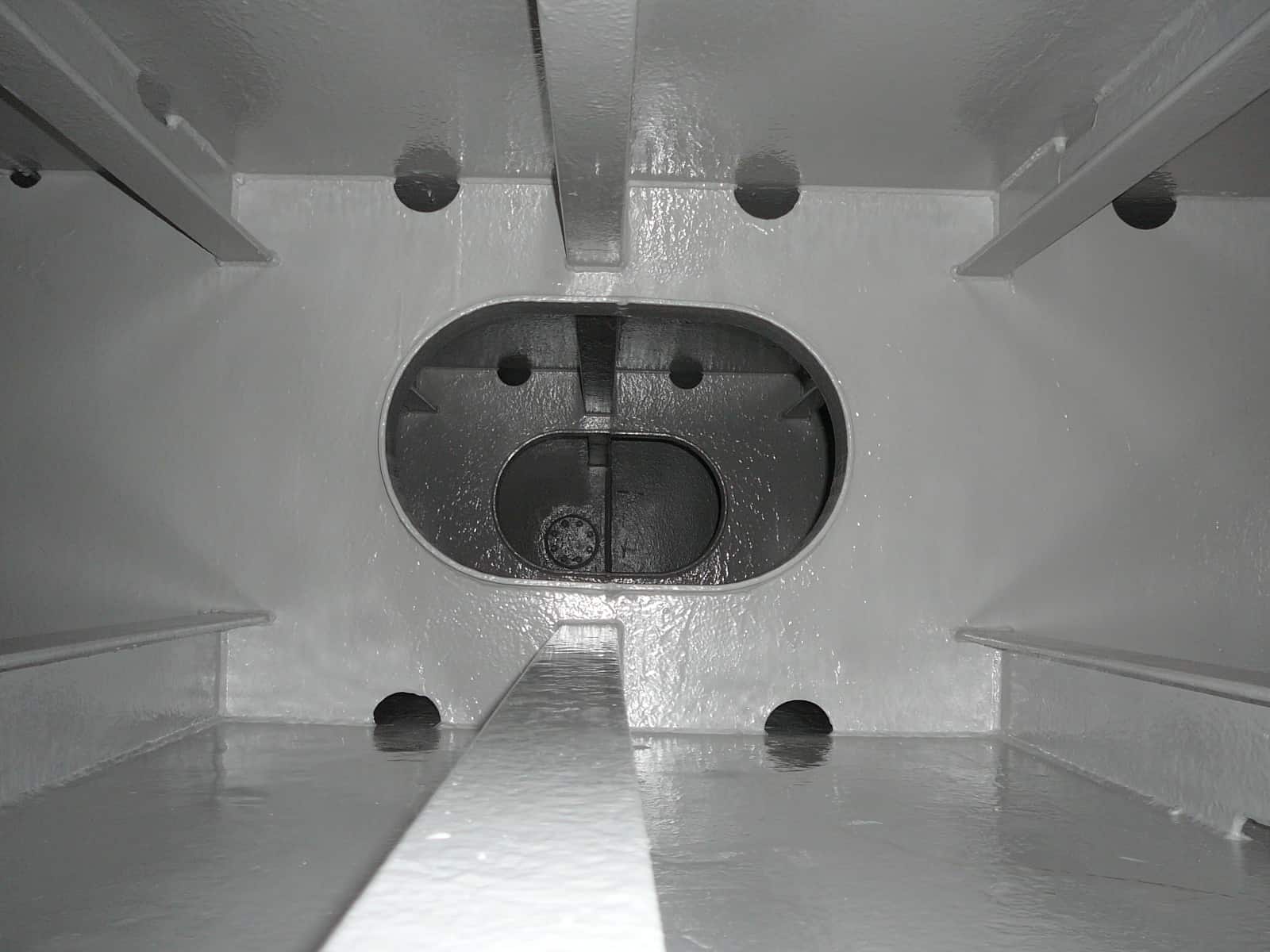

RA 300 is a 100% solid, glassflake reinforced, vinylester coating system.

It provides exceptional resistance to severe chemical, corrosive and abrasive environments.

RB 300 is a 100% solid vinylester coating system, reinforced with glassflake.

This coating is typically used as a tank lining system offering excellent resistance to the most aggressive chemicals at high temperature such as acids and solvents.

RB 300C is a 100% solid, vinylester coating system.

It is typically used for applications where high chemical resistance and conductivity are required.

RB 300P is a 100% solid, vinylester coating system.

It is typically utilised as a primer coating for improving adhesion to difficult substrates such as concrete, steel, glass and fibreglass.

RC 300 is a 100% solid, vinylester coating system.

It is suitable for specialist applications and as a repair material.

RD 300 is a 100% solid, vinylester coating system.

It offers exceptional chemical and high temperature resistance.

RE 300 is a 100% solid, vinylester coating system.

It offers exceptional chemical and high temperature resistance.

RF 300 is a 100% solid, vinylester coating system.

It has been specifically designed with exceptional high temperature resistance operating in the most severe chemical, corrosive and abrasive environments.

SOLUTIONS

Polyester Primers

RA 200 is a 100% solid, polyester coating system which has been reinforced with glassflake.

This system is typically used as a tank lining system offering exceptional resistance to harsh chemical environments.

RA 200C is a 100% solid, polyester coating system.

It is typically used for applications where high chemical resistance and conductivity are required.

RE 200 is a 100% solid, polyester coating system.

It provides exceptional chemical resistance for steel and concrete surface, specifically in the offshore industry.

RE 200P is a 100% solid, polyester coating system.

It is suitable for application to concrete, glass, steel, polyester and fibreglass substrates.